1. Service behaviors and life evaluation of materials and components for power plants

2. Environmentally-assisted cracking (SCC and CF) in high temperature pressurized water

3. Grain boundary engineering and control for metallic materials

4. Advanced materials (high entropy alloys and additive manufactured alloys) for high temperature corrosion resistance

5. Online monitoring techniques of material failures in extremely complex environment

- Project 1: “Grain boundary network design to prevent intergranular stress corrosion cracking of 316L stainless steel”, Beijing Natural Science Foundation, total fund 200000 RMB, 2025-2027.

- Project 2: “Evaluation of material ageing effects of main pipeline components and development and application of xx power ageing data platforms”, National Key Research and Development Program of China, total fund 180000 RMB, 2019-2023.

- Project 3: “Thermal ageing degradation of welded joint properties of 316LN stainless steel”, Fundamental Research Funds for the Central Universities, total fund 200000 RMB, 2020-2022.

- Project 4: “Study of effects of grain boundary network characteristics on intergranular stress corrosion cracking of austenitic stainless steel by using three-dimensional characterization”, National Natural Science Foundation of China, total fund 260000 RMB, 2018-2020.

- Project 5: “Study on intergranular degradation and grain boundary enhancement of austenitic stainless steel in supercritical water”, Beijing Natural Science Foundation, total fund 200000 RMB, 2018-2020.

1. Stress corrosion cracking: grain boundary engineering

Intergranular corrosion (IGC) and intergranular stress corrosion cracking (IGSCC) are the main failure mechanisms of austenitic stainless steels in high temperature water. For austenitic alloy materials such as austenitic stainless steel (316L, 304) and nickel-based alloys (690, 600, 625) used in thermal power stations, the grain boundary engineering (GBE) treatment was developed and used to control the grain boundary characteristic distribution of these materials, and a high fraction (>75%) of low-∑ coincidence site lattice (CSL) boundaries, most of which are twin boundaries (∑3), were formed. The low-∑ CSL boundaries can significantly improve the resistance to intergranular corrosion and IGSCC.

Figure: (a) The intergranular cracks mapped using EBSD and OM in a 1/2T CT specimen of 316 stainless steel after SCC test in high temperature water, and the normalized cracking susceptibility of each types of grain boundaries. (b) The slow strain rate tensile test (SSRT) of a GBE-treated and a conventional 304 stainless steel specimens in high temperature water shows that the GBE-treated 304 stainless steel has lower susceptibility to IGSCC.

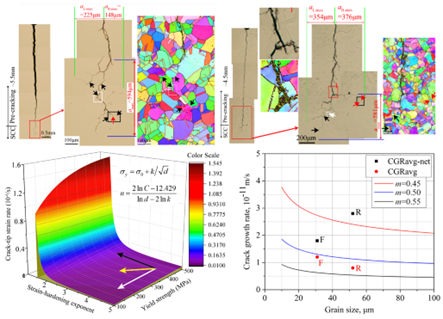

2. Stress corrosion cracking: crack growth rate

Stress corrosion cracking (SCC) of 316L stainless steels manufactured with different procedures were investigated in high temperature water. The effects of grain boundary network on SCC are discussed. Twin boundaries show stronger resistance to SCC than other types of boundaries. Grain size has significant influence on SCC though residual strain has more effect. Smaller grains result in more SCC initiation sites, while larger grains result in that the crack propagates locally deeper due to less restrictions from less triple points in the grain boundary network. Theoretical calculation is implemented to estimate the grain size effect on crack propagation.

Figure: Stress corrosion cracking of 316L stainless steels manufactured with different procedures: effects of grain size on stress corrosion cracking growth rate.

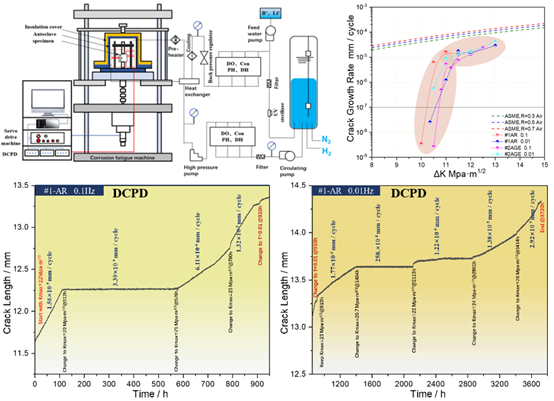

3. Corrosion fatigue: crack growth

The corrosion fatigue crack growth (CFCG) behaviors of Z3CN20.09 before and after thermal aging were studied in high temperature water. DCPD was used to monitor the crack growth, and constant K was loaded on the CT specimens to reveal the effects of ∆K on CFCG. The corrosion fatigue crack tip morphologies and fracture features were subsequently analyzed by using SEM and EBSD.

Figure: Corrosion fatigue crack propagation of Z3CN20.09 in high temperature water: Schematic diagram of the test equipment, the da/dN-∆K curves, and crack growth monitored curves by DCPD.

4. Grain boundary engineering: 3D-EBSD characterization of 316L stainless steels

The 3D-EBSD microstructure of 316L stainless steel specimens was collected by the method of ‘cross-sectioning + EBSD characterization’, and the geometrical features of 3D grains and grain boundaries were analyzed. It is concluded that the geometrical parameters of grains and grain boundaries obey lognormal distribution, and the statistical relationship between each parameter and grain size conforms to power function relationship. The three-dimensional geometrical features of twin boundaries are analyzed, and the number distribution of twin boundaries in triple-junctions, quadruple-junctions and on grains are counted.

Figure: 3D-EBSD microstructure of a 316L stainless steel

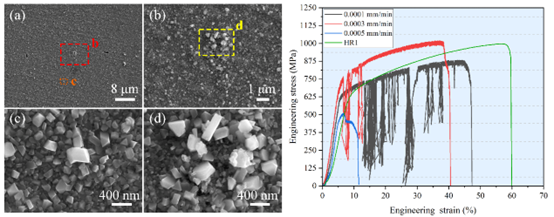

5. High entropy alloy: thermal power application

The development and research of Co-free high entropy alloys (HEAs) were carried out for high temperature corrosion resistance. The mechanical properties and corrosion and environmentally-assisted cracking in high temperature water of AlxCrFeNi(2-x)Ti0.2 HEAs were systematically studied. The results show that the eutectic microstructure has ultra-high strength but poor corrosion resistance. The FCC microstructure has high mechanical properties and good corrosion resistance, and the stress corrosion cracking at low strain rate shows a spontaneous healing behavior.

Figure: The oxide morphology and SSRT curves of a AlxCrFeNi(2-x)Ti0.2 HEA in high temperature pressurized water.

[1] T. Liu, Grain boundary engineering and three-dimensional characterization of metallic materials, China Science Publishing & Media Ltd., Beijing, 2020.

[2] T. Liu, J. Zhang, X. Zhang, C. Su, Y. Lu, T. Shoji, A dual eutectic high entropy alloy with superior strength and elasticity limit, Mat Sci Eng A, 927 (2025) 147974.

[3] J. Zhang, J. Yang, T. Liu*, D. Tian, H. Liu, G. Yang, Y. Lu, T. Shoji, Microstructure and mechanical properties of Co-free AlCrFeNiTi0.2 eutectic high-entropy alloy, J Mater Res Tech, 33 (2024) 6688-6700.

[4] X. Chen, D. Tian, L. Ling, T. Liu*, H. Wang, Y. Chen, Y. Lu, Microstructure and corrosion resistance of Z3CN20.09M stainless steels after different thermo-mechanical processing, J Nucl Mater, 577 (2023) 154300.

[5] T. Liu, S. Xia, T. Shoji, Intergranular stress corrosion cracking in simulated BWR water of 316L stainless steels manufactured with different procedures, Corros Sci, 183 (2021) 109344.

[6] T. Liu, S. Xia, D. Du, Q. Bai, L. Zhang, Y. Lu, Grain boundary engineering of large-size 316 stainless steel via warm-rolling for improving resistance to intergranular attack, Mater Lett, 234 (2019) 201-204.

[7] T. Liu, S. Xia, Q. Bai, B. Zhou, L. Zhang, Y. Lu, T. Shoji, Three-dimensional study of grain boundary engineering effects on intergranular stress corrosion cracking of 316 stainless steel in high temperature water, J Nucl Mater, 498 (2018) 290-299.

[8] T. Liu, S. Xia, B. Zhou, Q. Bai, G.S. Rohrer, Three-dimensional characteristics of the grain boundary networks of conventional and grain boundary engineered 316L stainless steel, Mater Charact, 133 (2017) 60-69.

[9] T. Liu, S. Xia, T. Shoji, Q. Bai, B. Zhou, Y. Lu, The topology of three-dimensional grain boundary network and its influence on stress corrosion crack propagation characteristics in austenitic stainless steel in a simulated BWR environment, Corros Sci, 129 (2017) 161-168.

[10] T. Liu, S. Xia, B. Wang, Q. Bai, B. Zhou, C. Su, Grain orientation statistics of grain-clusters and the propensity of multiple-twinning during grain boundary engineering, Mater Design, 112 (2016) 442-448.

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026