Researchers

Position:Home首页 > Scientific Research > Researchers

Professor Xue-Chong Ren

Keywords:Structural Metallic Materials; Fatigue and Fracture

Contact:xcren@ustb.edu.cn

Researches

Prof. Ren graduated with the B.S. / Ph.D. degree from Northeastern University and University of Science and Technology in 2000/2007 respectively, majored in material science and engineering.

Prof. Ren is the manager of mechanics and structural engineering laboratory in National Center for Materials Service Safety, University of Science and Technology, Beijing (USTB).

The research of Prof. Xuechong Ren is mainly focused on the relationship between microstructure, mechanical behavior and service performance of structural metallic materials, materials failure mechanism and structural reliability evaluation, including:

1. Materials fatigue and fracture

2. Hydrogen embrittlement and stress corrosion of materials

3. Numerical simulation of materials mechanical behavior

4. Research and development of advanced structural metallic materials

5. Performance evaluation on materials-components-structures cross-scale system.

l Main Projects

- Project 1:“National Natural Science Foundation of China”, Study on the Mechanism of Hydrogen Embrittlement Sensitivity of Bainite Wheel Steel, total fund 250000 RMB, 2010-2012.

- Project 2:“National Natural Science Foundation of China”, “Fracture and Ductile-Brittle Transition Mechanism of Wheel Steel for High Speed Railway”, total fund 600000 RMB, 2012-2015.

- Project 3:“National Natural Science Foundation of China”, Research on Key Technology and Evaluation Method of Wheel-axle Reliability Test for EMU, total fund 800000 RMB, 2013-2016.

- Project 4: “National Key Basic Research Projects” Study on Multiaxial Fatigue Damage and Structural Restraint Brittleness Mechanism of Wheel Materials, total fund 1200000 RMB, 2015-2019.

l Main Contributions

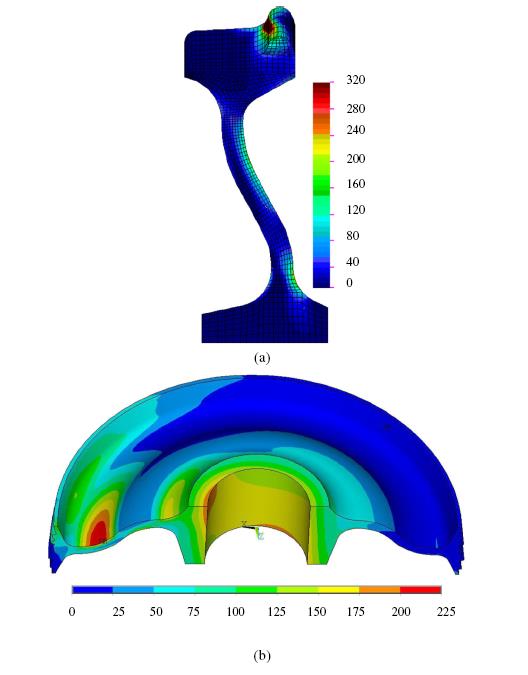

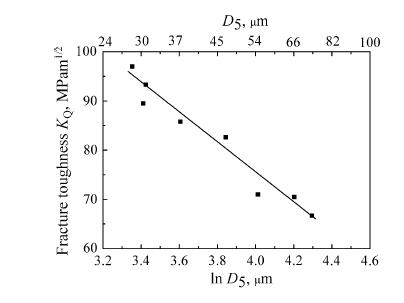

- Finite element method (FEM) and Sines' criterion were used to evaluate the safety of the wheels with corrosion pittings. The results showed that the wheel plates without corrosion pits exhibited an excellent resistance to failure. The corrosion pits could promote the initiation of fatigue cracks and drastically lower the fatigue limits of corroded specimens. A critical depth of the corrosion pit on the wheel plate 300 μm was recommended.

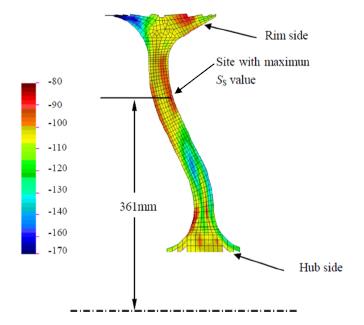

- When the grain size is inhomogeneous, the cleavage fracture toughness depends mainly on the diameters of the larger grains. For heat treated wheel steel, the fracture toughness KQ increases with decreasing average size of the top 5 pct grains D5. When the austenitization temperature is same, rapid heating not only can refine the grain size but also make the grain size homogeneous, thereby improving the fracture toughness.

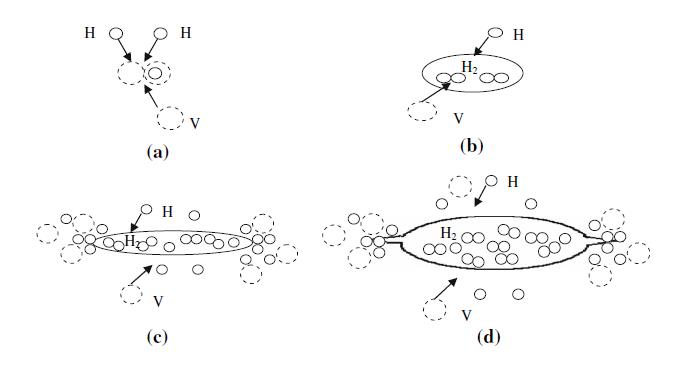

- An approach of the nucleation mechanism of hydrogen blister is proposed. Atomic hydrogen can induce superabundant vacancies in metals. The superabundant vacancies and hydrogen aggregate into a hydrogen-vacancy cluster (small cavity). The hydrogen atoms in the hydrogen-vacancy cluster become hydrogen molecules that can stabilize the cluster. And the hydrogen blister nucleates. The pressure in the small cavity increases as the hydrogen atoms enter the cavity. The cluster, that is, the hydrogen blister nucleus, grows through vacancies diffusing into it under the action of cluster-hydrogen binding energy and hydrogen pressure. When the blister nucleus grows to a critical size Ccr cracks will initiate from the wall of the cavity due to the internal hydrogen pressure.

……

l Publications

1. Ren X C, Chu W Y, Su Y J, Li J X, Qiao L J. The effects of atomic hydrogen and flaking on the mechanical Properties of a wheel steel. Metallurgical and Materials Transactions A, 2007, vol. 38(5), 1004-1011.

2. Ren X C, Zhou Q J, Shan G B, Chu W Y, Li J X, Su Y J, Qiao L J. A nucleation mechanism of of hydrogen blister in metals and Alloys. Metallurgical and Materials Transactions A, 2008,vol.39(1),87-97.

3. Ren X C, Chu W Y, Su Y J, Li J X, Qiao L J, Jiang B, Zhang M R, Chen G. The effects of atomic hydrogen and flake on mechanical properties of a tyre steel. Materials Science and Engineering A, 2008, vol.491,164-171.

4. Ren X C, Chu W Y, Li J X, Su Y J, Qiao L J. The effects of inclusions and second phase particles on hydrogen-induced blistering in iron. Materials Chemistry and Physics, 2008, vol. 107, 231-235.

5. Ren Xuechong, Liu Fenbin, Wang Shasha, Chu Wuyang, Su Yanjing, Qiao Lijie. Hydrogen embrittlement of a bainitic wheel steel. TMS139th Annual Meeting, 2010, v 3, p 413-427.

6. Xuechong Ren, Lixin Zhang, Yingfeng Chen, Fengyan Sun, Weidong Zhang, Lili Lin, Yinling Wang. Tensile and fatigue properties of 7050 aluminum alloy axle box used for high speed train. Procedia Engineering, 2012, vol.27, 914 – 922.

7. Xuechong Ren, Fei Wu, Feng Xiao, Bo Jiang. Corrosion induced fatigue failure of railway wheels.Engineering Failure Analysis, 2015, 55, 300–316

8. X. C. Ren, J. Qi, J. Y. Gao, L. Wen, B. Jiang, G. Chen, H. Zhao. Effects of Heating Rate on Microstructure and Fracture Toughness of Railway Wheel Steel. Metallurgical and Materials Transactions A, 2016, 47 (2): 739-747

l Books

1. Chu Wuyang, Qiao lijie, Li Jinxu, Su yanjing, Ren xuechong et al. Hydrogen Embrittlement and Stress Corrosion Cracking. Beijing, Science Press, 2013.11, ISBN 978-7-03-038884

l Patents

1. A Heat Treatment Method for Toughening Wheel Steel, ZL201110172527.9

2. A Thermal-Mechanical Coupled Fatigue Testing Device and Method. ZL201210077678.0

3. A Device for Direct 3D Printing Manufacturing with Liquid Metal. ZL201510788846.0