Aims

In-situ test platform for high energy synchrotron radiation light source was constructed basing on the High Energy Photon Source-Testing Facility (HEPS-TF) project. It focuses on the intrinsic relationship between composition, organization/structure, and performance of engineering materials in the entire life cycle of "fabrication-processing-service". With the goal of improving the research capability of "real service properties of real materials under real conditions in real time" (4R), it utilizes the high energy X-ray with high resolution, high penetration depth and ultra-fast characteristics combined with absorption, diffraction, imaging and other technologies to carry out in-situ researches on liquid-solid interface, deformation properties of materials and corrosion behavior of materials. This In-situ test platform will improve the full-scale characterization system of NCMS.

Specification of in-situ test systems

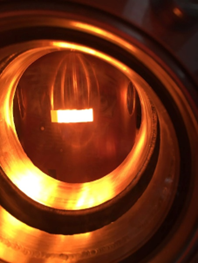

In-situ characterization system for liquid-solid interface structure of engineering materials: Vacuum: 1×10-2Torr, Max Temperature: 1600℃, Temperature fluctuations: <10℃

In-situ deformation test system for engineering materials: Loading methods: Tensile/Compression/Torsion/Rotation, Max axial load/Max torque: ±15kN/ ±20Nm, Max temperature: 1200℃, Max rotation angle: ±110°

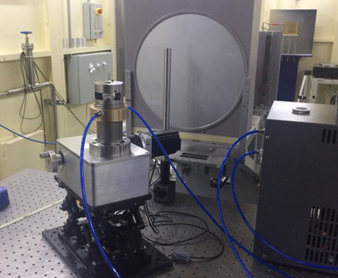

In-situ characterization system for materials in service: High-pressure corrosion solution environment simulation, Salt spray/CO2 environment simulation, Hydrostatic Pressure: 0~40MPa, Temperature range: 0~25℃

Test Capability

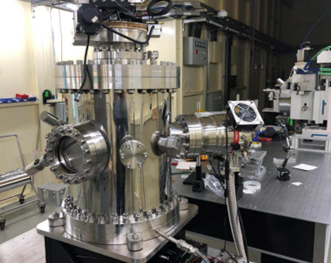

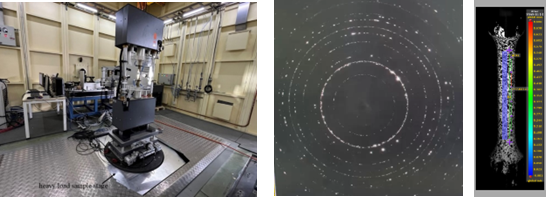

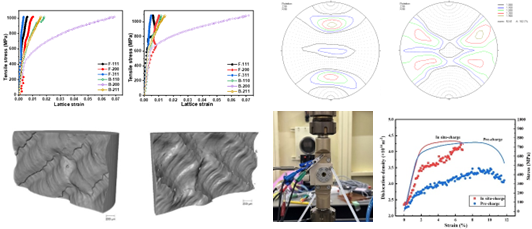

The universal in-situ deformation test system has been installed successfully at the beamline BL12SW of Shanghai synchrotron radiation facility. The in-situ testing system was designed to apply multiple functions including tensile/compression and the simultaneously rotation along the tensile axis, as well as the electric heating of the metallic specimen. Two electrical torsional actuators enable the ω-rotation of the specimen along the tensile axis without blocking the beam by the columns of the loading frame. Digital video extensometer was utilized to measure the deformation strain avoiding any contact with the specimen. Lattice strain partitioning, texture evolution and imaging experiments have been conducted successfully. One electrochemistry in-situ hydrogen charging cell was developed to study the structural changes of the material during mechanical loading.

The customized in-situ testing system installed at Shanghai synchrotron radiation facility (SSRF) beamline BL12SW

The in-situ researches conducted successfully by the customized in-situ testing system, including strain partitioning (Top left), texture measurement (Top right),

quai in-situ imaging (Bottom left) and the deformation behavior of materials with in-situ hydrogen charging (Bottom right)

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026