These devices are used to study the service life and reliability of materials and components in industrial and natural environments. By using the devices, equivalent accelerated testing and failure process of full-scale engineering materials or components under actual service conditions are carried out.

Test Capability

1.Test of standard materials specimens, shrinkage components, full-scale components, complex structures

2.Material and components test under mechanical loads and service environments simultaneously

3.Hybrid simulation test and remote test for component performance

4.Creep test (80℃~1600℃, subcritical water, melten salt, coal-fired flue gas etc.)

Research Direction

1.Size effect and environmental effect of fatigue and fracture of materials and components

2.Material-component-structure integration performance test, life prediction and safety evaluation method

3.Digital-physical fusion method for material service performance prediction of key components

4.Distributed multi-site interconnection test technology for super large structure

5.Creep performance and creep mechanisms of metallic materials in corrosion environment

Advantages of the Facility

These devices realize comprehensive evaluation test of service performance of large/full-size materials or components in multi-field coupling environment.

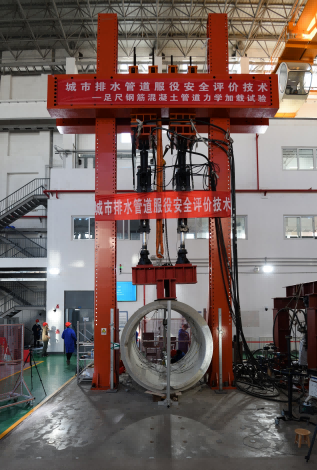

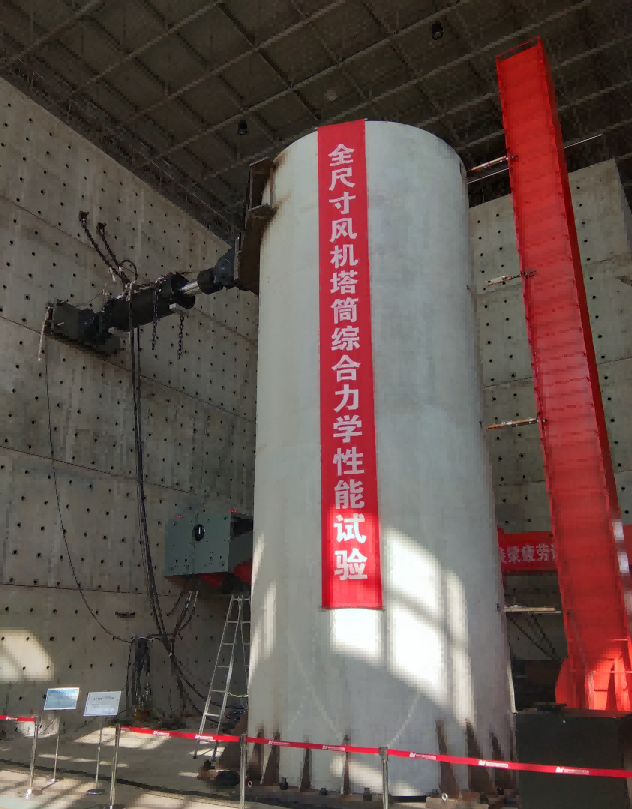

Full-scale reinforced concrete sewer pipe loading test Mechanical properties test of full scale structure for wind generator tower

Creep test machines

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026